WCMBR-10 Marine Sewage Treatment Plant:

Description:

The method of combining catalytic oxidation and physical disinfestations and sterilization is adopted in the WCMBR series domestic sewage treatment device; it treats the domestic sewage of kitchens, W.C.,and base room from ship. Since filler is set in the aeration chamber, the chlorine adding sterilization si adopted,so compare with the products of the same kind, it has the characteristics of small cubage, light weight, compact structure and without secondary pollution. The discharged water after the treatment of the device has reached the effluent standard stipulated internationally, and it accords with the requirement of Resolution MEPC.159(55) of International Marine Organization Environmental Protection Commission, and International waste fluid effluent standard.

Principle:

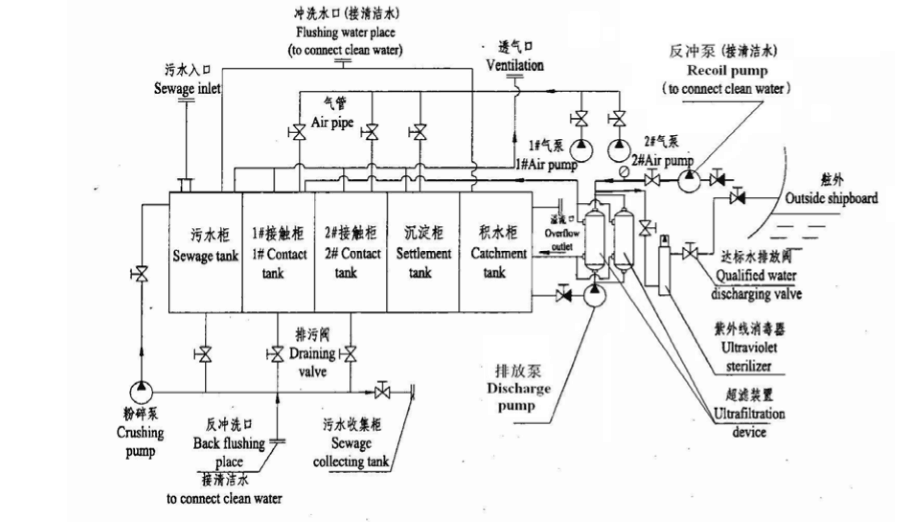

After the sewage from toilet crushed completely flows into the sewage tank by the way of nature inflow to contact oxidation tank to aerate by air pump, and to contact with biofilm by a certain velocity flowing though fillings. The organic pollutant will be digested by biofilms, and CO2 and water are generated. After further treatment of the biofilem in the second contact tank, the sewage will flow into settlement tank for settlement and deslagging, and then is sent to catchment tank. When the catchment tank collects a certain amount of liquid, the process pump is started and the liquid is put into the ultrafilter to filter the slag by the water pump. The ultraviolet sterilizing plant kills the bacteria in the fluid, and treated water is discharged overboard as an effluent. The sludge in the settlement tank will be returned to first -stage contact tank in airlift device , which will cause a certain back flow ratio. This will enhance output water quality, reduce input water impurity, adjust and stabilize pulse loading, and increase activation of biofilm, improve improve organic loading rate in the contact tank.

Technical Data:

|

Model |

WCMBR-10 |

|

Suitable Number of People |

10 |

|

Treatment load t/d |

0.77 |

|

Organic load kg/d |

0.39 |

|

Drain standard |

BOD5≤25mg/l, COD≤125mg/l,TSS≤mg/l, Coli group≤100pcs/100ml |

|

Ulitrafilter |

Advanced anti-soil ultrafiltration membrance |

|

Back flushingwater pressure |

0.1-0.25Mpa |

|

Power supply |

3Phase/AC380V/50HZ or

3Phase/AC440V/600HZ |

|

Control mode |

Automatic/Manual |